Research, innovations

and education

AREA, STRATEGIC GOALS AND HIGHLIGHTS OF 2024

Target

12.4

Improvement of production processes to ensure high quality and eco‑friendliness of our products, including a process for the development of new products that respects safety and the environment throughout its life cycle

- Efforts are underway to develop solutions for mining and processing diatomite with a view to producing our own vanadium sulphuric acid catalyst

- We continue to boost in‑house power generation by capturing heat from chemical reactions in sulphuric acid production

- A project is underway to treat mining water from the Kirovsky and Rasvumchorrsky mines

- In collaboration with the Kolsky Research Centre of the Russian Academy of Sciences, we are advancing research on ore beneficiation and improving the efficiency of recovering valuable components into mineral concentrates

Target

9.4

Strengthening the Company’s technological sovereignty and expanding the capabilities of its IT infrastructure. Development of artificial intelligence solutions will not only enhance production efficiency, but will also make work more comfortable and safer for employees

- We continued implementing a domestic automated enterprise management system and automated process control system.

- With more than 180 robots already in operation, we are scaling up their use and integrating them into key business processes

- The Company migrated its internal communications to eXpress, a Russian corporate platform

Target

2.4

Promotion of sustainable farming practices, development of new fertilizer grades for increased availability of best practices in farming

- We conducted in‑depth testing to study the carbon footprint of traditional mineral fertilizers and their biologised alternatives

- We patented a technology for producing biologised fertilizers, securing two patents for innovative methods of manufacturing biologised NP fertilizers

- We developed prototypes of protected feed grade urea, offering a safe and efficient source of non‑protein nitrogen for cattle

Target

13.1, 13.2,

15.1

Soil safety, biodiversity conservation, fertility growth and lower GHG emissions in agricultural production and throughout the product’s life cycle from mine to plate

- We tested carbon dioxide sequestration in forage grasses using the Company’s fertilizers, including locally cultivated forage crop varieties

- We received the results of tests conducted to study the carbon footprint of mineral fertilizers and their biologised alternatives. The tests showed a reduction in carbon footprint by 8–35%

- We launched a pilot to establish an interregional testing network for evaluating the carbon footprint of the Company’s fertilizers

- We conducted a production trial using biologised adaptive plant nutrition systems and a biological preservative for forage conservation

- The Company continues to grow its digital learning programme for Russian and foreign farmers, Pro Agro Lectorium

- We launched the RECSOIL project in Russia in partnership with Lomonosov Moscow State University and UN FAO

Target

4.4, 17.16,

17.17

Implementation of a comprehensive phased programme to support sustainable agricultural practices and support young scholars in running sustainable development projects

- The BRICS International School for Sustainable Agriculture was launched, bringing together 60 students from six BRICS nations

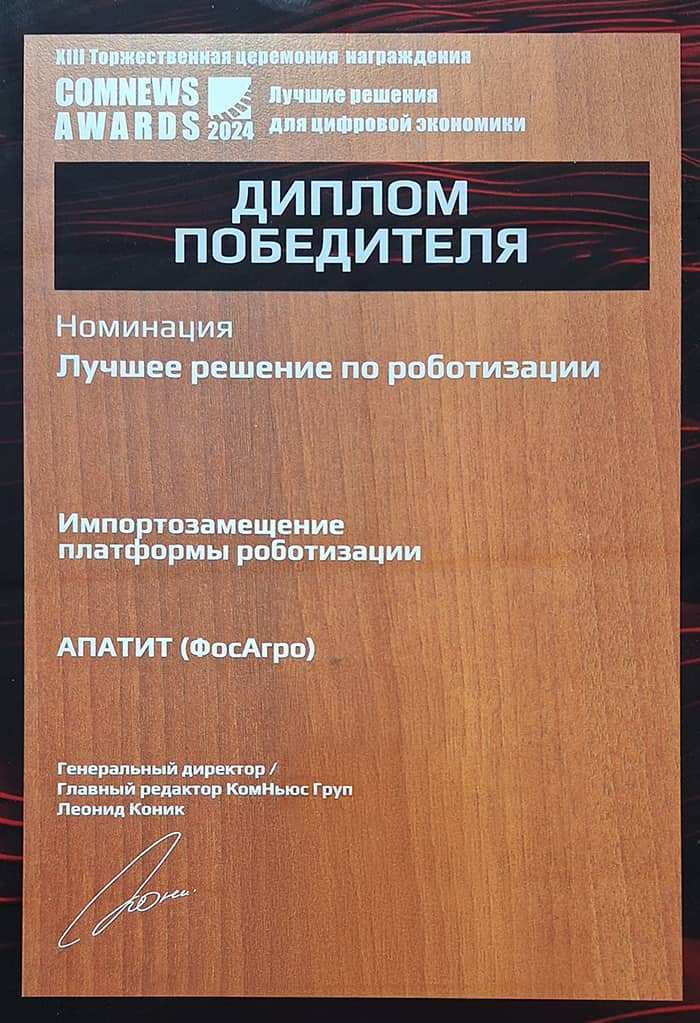

In December 2024, PhosAgro Group won the competition ComNews Awards.Best Solutions for Digital Economy.

In November 2024 PhosAgro’s electronic HR document management system received an honour at CNews Awards 2024.

PhosAgro’s ProAgro Lectorium e‑learning platform for foreign farmers received a well‑deserved praise and won at the BRICS Solutions Awards2024, an international competition held as part of the BRICS Business Forum.

The Company’s innovations in fertilizer production are a sustainable development driver in agriculture and make a meaningful contribution to strengthening cooperation for food security.

PhosAgro Group seeks to ensure efficient and safe agricultural production and develops innovative fertilizers while also working hard to minimise the environmental impact of mineral fertilizer application and production. In doing so, the Company relies on Russian and international experience and leading research and production practices.

Our Strategy to 2025 envisages efforts to increase the share of innovative products, develop technology and production, and ramp up potential for cooperation with stakeholders and partners in the area of innovation and research.

In 2023, the Company developed the Import Substitution Strategy and the Import Substitution Programme, ensuring systematic migration to domestic software platforms and the implementation of key infrastructure projects.

GRI 3‑3

Our innovation, product development, and research and education management system is seamlessly integrated into the overall management framework covering all Company processes.

PhosAgro Group runs the Samoilov Scientific Research Institute for Fertilizers and Insectofungicides (NIUIF), Russia’s only institute specialising in this area.

PhosAgro Innovation Centre was established in 2018 to create cutting‑edge products and technologies in partnership with research institutions in Russia and abroad. The NIUIF and PhosAgro Innovation Centre bring together world‑class researchers, engineers, and experts from various areas to address the most complex operational issues as well as applied and fundamental research problems.

The Group actively cooperates with the Ministry of Agriculture, the Russian Academy of Sciences, federal research centres, universities, innovation funds, and international R&D organisations (University of Belgrade and Brazil’s Federal University of Lavras), along with recognised international organisations with a view to providing broad support to humanitarian and research‑intensive projects.

Apatit’s IT Department established a division for developing artificial intelligence solutions to drive the integration of advanced AI technologies into the Company’s key business processes. The team is focused on three core areas: machine learning, video analytics, and generative AI. The computing capabilities are supported by a GPU‑powered server cluster housed by the Company’s corporate data centres.

Research and education fall within the remit of the Technical Development Department and are discussed at the meetings of the Strategy and Sustainable Development Committee of the Board of Directors. These matters are subject to an annual review by the Board of Directors.

The Company’s operations span the entire production cycle from mining apatite‑nepheline ore and processing it into mineral fertilizers to their end use by consumers.

Combined with our efforts to develop advanced and efficient plant nutrition systems, this creates a wide network of stakeholders which we seek to engage with on a priority basis. In its scientific and educational pursuits, the Company collaborates with such stakeholders as scientific institutions, university research teams, the global community and international organisations. To drive innovations and the latest information technologies, we work closely with the Company’s departments and divisions, all production units across the Group’s branches, and PhosAgro’s employees and counterparties. Our key stakeholders also include regional authorities, non‑governmental organisations, schoolchildren, their parents and educators.

We are committed to fostering partnerships with the scientific community, international organisations and universities through joint working groups and collaborative projects aimed at driving innovations, enhancing the reputation of Russian science, and unlocking its full potential.

Among other things, the following strategic risks affect our research and educational objectives

environmental risk

regulatory risk

climate risk

non‑compliance of products’ manufacturing process and their use with carbon footprint standards and other environmental requirements;

insufficient environmental friendliness of production processes;

non‑alignment of plant nutrition systems with specific farming conditions;

lack of awareness about the Company’s products and services, coupled with the level of expertise prevailing among agricultural professionals both in Russia and abroad.

The Group develops corrective measures as necessary and unlocks opportunities, including import substitution, to mitigate those risks. Below you can find more information about what we do on this front.

Development of proprietary technologies and import substitution solutions

Introduction of new fertilizers with enhanced environmental safety, improved biological availability, and adaptability to the climate change

Opportunities related to the development of partnerships in science, education, and awareness raising

At the same time, in addressing climate change, related soil degradation processes and the growing world population, the Company recognises its role as a responsible producer that contributes to global food security. PhosAgro is actively engaged in:

- developing sustainable products and nutrition systems;

- promoting responsible agricultural practices;

- combating climate change across value chains.

To achieve these goals, we leverage our accumulated expertise and innovative potential, while also working closely with partners in the fields of science and business.

For more information, see the Strategic Risks section

MED 4

Investments in R&D activities and development of new products, RUBmln

Improvement of ore extraction and processing

The Company is developing key technical solutions for mining and processing diatomite with a view to producing its own vanadium sulphuric acid catalyst. In 2024, we developed as‑built documentation for the design and construction of the vanadium sulphuric acid catalyst plant.

In collaboration with the Kolsky Research Centre of the Russian Academy of Sciences, we continue to explore ore beneficiation and ways to increase production volumes. The Company is developing a roadmap for making products from low‑grade and off‑balance ores, tailings of ANBP‑1, 2 and 3, and slurry discharges. In 2024, we collected samples and transferred them to the Kolsky Research Centre so that it could develop the concentrate for further research into production options.

To enable the mining of a block pillar under the Saami pit, we continue to divert the Gakman and Loparskaya rivers.

The project to develop the reserves of the Rasvumchorr Plateau deposit through underground mining is now subject to design supervision and construction control, with the diversification of coolants at the main ventilation and hot‑air heating unit (use of liquefied natural gas at the Rasvumchorrsky mine) designed to improve energy efficiency and reduce pollutant and GHG emissions.

Production efficiency improvements and introduction of elements of circular economy

Improving the efficiency of using resources, including water, and increasing the energy efficiency of production processes are crucial tasks for the Company.

With the loads of process systems increased following the upgrade of wet‑process phosphoric acid production units in Cherepovets, Volkhov and Balakovo, we reduced our specific power consumption.

The NIUIF team completed a broad range of tasks related to increasing performance, including the development of draft technical specifications and the validation of measurement methods for food grade and technical grade purified phosphoric acid and feed phosphates, and state registration of the Company’s new fertilizer grades.

One of the standout projects involves the development of technical solutions to extend the maintenance intervals for sulphuric acid systems to three years. In 2024, we developed key technical solutions for the tail gas treatment unit designed to reduce sulphur dioxide content in emissions from sulphuric acid systems.

Another important strategic task completed in 2024 was the development of key technical solutions for the liquid sulphur dioxide production unit.

Implementation of a domestic automated enterprise management system and automated process control system

PhosAgro Group is a member of the Chemistry and Pharmaceuticals industrial competency centre (ICC). In this capacity, it acts as the anchor customer for the projects to introduce a domestic automated enterprise management system and automated process control system. These projects are co‑funded by the state through the Skolkovo Foundation and are being implemented at the Cherepovets production site.

In 2024, the development of the automated enterprise management system was completed, and now it is being piloted. The new enterprise management system offers comprehensive data collection tools and data visualisation across the entire range of processes, calculates technical and economic indicators, and generates production reports. The platform architecture is based exclusively on domestic solutions. The project involved the creation of more than 800 mnemonic diagrams and collection of over 60,000 indicators from 33 sources. To populate the system with data, experts from PhosAgro’s Engineering Centre developed special software solutions to automatically transfer calculations and mnemonic diagrams from the old system to the new one. The platform’s scaling to other production sites is slated for 2025–2026 following a test run and performance analysis.

The second project aims to develop an automated process control system and implement it at continuous chemical production sites. Launched in late 2022, the project focuses on replacing imported software and hardware with domestic products.

The automated enterprise management and process control systems are of crucial importance for chemical production, as they are indispensable for today’s management approaches and high level of process automation. Migration to domestic software ensures not only technological independence, but also the stability of production processes.

Import substitution project to replace PhosAgro’s robotisation platform

The Company presented a project on the import substitution of its business process robotisation platform, which covers all of the Group’s companies. The project to introduce a domestic platform was launched back in 2023. The application of robotics led to a 34% reduction in the time it takes to prepare corporate reports. Thanks to the project, the Company migrated some 50% of its business processes to the Russian platform. The development approach was standardised through the introduction of a coding agreement, best practices, version control systems and code compliance checks. This helps shorten implementation time, reduce maintenance costs, and improve business transparency.

Other import substitution projects completed in 2024:

substitution of the RPA software robot development system with the domestic RPA PIX Robotics solution;

implementation of the domestic Vinteo video conferencing system to replace Cisco;

migration of internal communications to eXpress, a Russian corporate platform;

installation of domestically produced Protey PBX at the Cherepovets and Kirovsk sites;

replacement of Cisco ASA firewalls with the domestic Continent solutions;

overhaul of the Kirovsk site’s data centre, including the upgrade of the uninterruptible power supply system using domestic alternatives;

launch of a project to implement Global ERP, a Russian ERP system, as a replacement for Oracle eBS;

start of migration from Microsoft to Russian software, including Astra Linux OS, R7 office suite and the domestic directory service.

ECTLM (Unified Centre for Transport Logistics Management) visualisation system, which serves as a digital dispatcher for railway transport management

Energy Management system, which predicts electricity consumption at the Kirovsk branch through big data analytics

Mobile voice patrol, which enables track walkers to use voice recognition for filling out complex checklists

Development and scaling of predictive diagnostics for the central discharge ball mill at the Kirovsk branch

PhosAgro’s electronic HR document management system

Apatit’s electronic HR document management system (EPDMS) powered by WSS Docs started operating in a pilot mode in April 2024. As a result, the key HR documents that are essential for employees’ daily work or are generated as part of other processes were fully digitised.

With the new system, employees can produce HR documents from a desktop, a shared workstation or a mobile app. The process was streamlined to just a few steps: all the employee has to do is fill out a few fields in WSS Docs, and then the required document will be generated automatically. WSS Docs also supports electronic signature keys, which are issued, renewed and revoked by PhosAgro’s Certification Authority.

PhosAgro Group’s product mix comprised over 58 grades of fertilizers of all types in 2024. The Company’s Strategy focuses on developing products that address the evolving challenges faced by farmers, including solutions mitigating the impact of climate change. PhosAgro Group is currently preparing an updated version of its Development Strategy to 2030, which will encompass the production of:

- micronutrient fertilizers and NP/NPK blends with micronutrients and mesoelements;

- water‑soluble fertilizers;

- feed additives and feed phosphates;

- biological and biologised fertilizers;

- biological crop protection agents;

- growth enhancers.

The primary focus of all of these solutions is biologisation of agriculture, improvements in the quality of agricultural products, reduction of the environmental impact of chemicals in intensive farming, and introduction of specialised niche products, which will bolster crop yields and improve product quality, while also mitigating the climatic and environment impact.

Development of new fertilizers

Development of biologised fertilizers

In 2024, PhosAgro Group continued its research into the impact of biologisation on GHG emissions from fertilizers. In partnership with the Russian State Agrarian University – Moscow Timiryazev Agricultural Academy, the Caspian Federal Agrarian Research Centre of the Russian Academy of Sciences (CFARC of RAS) and Ulyanovsk Research Institute of Agriculture (URIA, a branch of Samara Federal Research Centre of the RAS), the Company ran in‑depth trials to study nitrogen emissions resulting from the use of both traditional mineral fertilizers and their biologised alternatives. The trials took place in the Astrakhan Region on irrigated lands typical for arid areas of risky farming, which are especially vulnerable to climate change and associated stress factors for plants and soils. Additional trials were carried out in the Ulyanovsk Region on chernozem soils with average national crop yield levels and without irrigation. The trials clearly demonstrated that biologised fertilizers contributed to an overall increase in biomass and a notable boost in marketable crop yield.

| Fertilizers | Nitrogen dosage, | CFARC of RAS (irrigation) | URIA (no irrigation) | ||

|---|---|---|---|---|---|

| Grain, t/ha | Straw, t/ha | Grain, t/ha | Straw, t/ha | ||

| Spring wheat | |||||

| Control (no fertilizer) | 0 | 2.04 | 3.07 | 2.58 | 1.97 |

| Urea N 46.2 | 30 | 3.48 | 5.22 | 3.13 | 2.43 |

| 120 | 6.02 | 8.23 | 3.16 | 2.45 | |

| Bio‑urea bio‑N 46.2 | 30 | 4.87 | 6,98 | 3.20 | 2.51 |

| 120 | 6.58 | 9.22 | 3.23 | 2.49 | |

| NPK(S) 10:26:26(1) | 12 | 4.23 | 6.21 | 3.33 | 2.59 |

| 46 | 4.27 | 5.81 | 3.54 | 2.77 | |

| Bio‑NPK(S) 10:26:26(1) | 12 | 5.12 | 7.35 | 3.05 | 2.36 |

| 46 | 4.34 | 5.94 | 3.33 | 2.59 | |

| Field peas | |||||

| Control (no fertilizer) | 0 | 0.82 | 1.11 | 2.57 | 1.99 |

| Urea N 46.2 | 30 | 4.20 | 5.85 | 2.96 | 2.33 |

| 60 | 5.46 | 7.46 | 2.89 | 2.26 | |

| Bio‑urea bio‑N 46.2 | 30 | 5.56 | 7.62 | 3.04 | 2.39 |

| 60 | 5.62 | 7.30 | 3.14 | 2.48 | |

| NPK(S) 10:26:26 (1) | 12 | 3.93 | 5.64 | 3.16 | 2.50 |

| 46 | 1.97 | 2.76 | 3.06 | 2.41 | |

| Bio‑NPK(S) 10:26:26 (1) | 12 | 5.20 | 7.28 | 3.25 | 2.58 |

| 46 | 2.26 | 3.16 | 3.14 | 2.48 | |

The trials demonstrated that using the Company’s biologised products (compared to traditional fertilizers) led to higher crop yields at the same application rate. Notably, these products also stimulated greater straw biomass production. When incorporated into the soil, this additional biomass can contribute to soil carbon accumulation.

In 2025, the Company plans to conduct second‑year interregional trials on similar crops. These trials will help expand and enrich the data array, offering deeper insights into how environmental and climatic factors influence nitrogen emissions from fertilizers applied at fields. They will also support the development of a mathematical model to predict and assess N2O emissions.

Currently, carbon footprint calculations rely on standardised emission factors and the IPCCIntergovernmental Panel on Climate Change. methodology, according to which the rate of fertilizer‑related nitrous oxide (N2O) emissions is estimated at 1% of the calculated nitrogen content in a specific fertilizer grade. However, the Company’s field experiments suggest that actual emissions may be lower. The emission rate depends on factors such as the dosage of nitrogen‑based fertilizers, fertilizer form, composition of the nutrition system, crop type, soil characteristics and climate conditions (see the table N‑N2O emission factor for different fertilizers).

| Option | Emission factor: N‑N2O, % |

|---|---|

| Urea N 46.2 (grade B, granulated) | 0.74 |

| Nitrogen‑based fertilizer bio‑urea bio‑N 46.2 | 0.65 |

| NP 12‑52 | 0.71 |

| bio‑NP 12‑52 | 0.63 |

| NP 18‑46 | 0.68 |

| bio‑NP 18‑46 | 0.55 |

| NPK (S) 15:15:15 (10) | 0.59 |

| Bio‑NPK(S) 15:15:15(10) | 0.56 |

| NPK(S) 10:26:26 (1) | 0.62 |

| Bio‑NPK(S) 10:26:26(1) | 0.56 |

| NPK(S) 8:20:30 (2) | 0.57 |

| Bio‑NPK(S) 8:20:30(2) | 0.52 |

An important task planned for 2025 will consist in integrating the results of biologised fertilizer trials and the data on nitrous oxide emissions into PhosAgro’s Agro Calculator. This metric will be synergised with other parameters to help calculate customised plant nutrition systems. With the Agro Calculator, users will be able to evaluate the carbon footprint of agricultural products and streamline relevant nutrition strategies to minimise emissions, which is of particular importance for products exported to markets with GHG border tariffs.

The Company plans to launch full‑scale production of biologised mineral fertilizers in 2025, with the first batch scheduled for release in 2026. The product line will include N, NP and NPK fertilizers, allowing for smooth integration of a biological component into the existing nutrition system through replacement of the traditional counterpart with a view to ensuring seamless transition to biologised farming. The technology enables the application of high concentrations of biologically active strains that are resilient to concentrated inorganic salts.

Manufacturing and sales of new products

Developed by PhosAgro’s Innovation Centre, ApaSil is designed for seed pre‑treatment and foliar application on a wide range of agricultural crops and ornamental plants. Field trials in different regions and on different crops have shown that this product helps plants cope with the stresses associated with drought and diseases.

Between 2019 and 2024, PhosAgro’s Innovation Centre conducted a comprehensive analysis to identify biological solutions suitable for Russian agriculture. Based on this research, the Group will expand its product range in 2025 with biological agents developed by partner companies such as Innopraktika, Bisolbi Plus, Biona Group, and Flora‑Si. The products will be sold through a network of 16 official regional distributors.

| Product name | Purpose |

|---|---|

| ApaSil | Adaptogen |

| Metabacterin | Biological fungicide |

| Fermasil | Dry silage inoculant |

| Enzymesporin | Probiotic feed additive |

| Extrasol | Biological growth enhancer |

| BisolbiSan | Biofungicide |

| Energia‑M | Combined growth enhancer |

| Effect Bio, SC | Stubble decomposer |

| Azofix, ZH (peas, lentils) | Inoculant |

| Azofix, ZH (chickpeas) | Inoculant |

| BioConsort Start | Amino acids for seed treatment |

| BioConsort Vegetation | Amino acids with micronutrients |

| Probactil | Liquid silage inoculant |

| Subtisporin | Liquid probiotic feed additive |

Development of feed additives

In 2024, PhosAgro Innovation Centre and the Mendeleyev University of Chemical Technology developed prototypes of protected feed grade urea, offering a safe and efficient source of non‑protein nitrogen for cattle. Jointly with the Skryabin Moscow State Academy of Veterinary Medicine and Biotechnology, we conducted production trials of the EnzymesporinWhen applied jointly with monocalcium phosphate. feed additive, which increased the live weight of calves by 8.7%. The products will be manufactured using our unique proprietary technology, and in 2025 we plan to patent and develop the technology to produce this additive.

In 2025, we plan to join efforts with the Skryabin Moscow State Academy of Veterinary Medicine and Biotechnology to test new feed additives that help reduce greenhouse gas emissions from milk production and address the prevention and treatment of cryptosporidiosis and parasitic infestations in farm animals. When used in conjunction with existing therapeutic products, the solutions we are developing will enable comprehensive animal care.

In 2023, at the livestock breeding complex, a branch of the Federal Williams Research Centre of Forage Production and Agroecology, we started trials of a biologised forage grass nutrition system with the Company’s fertilizer system, which will be completed in 2026. The data obtained will make it possible to develop a comprehensive forage growing programme and an animal nutrition system based on PhosAgro Group’s products.

| Item | Population at the beginning of the experiment, AUs | Survival, % | Average live weight at the beginning of the experiment, kg | Average live weight on the 40th day, kg | Live weight ratio in relation to benchmark, % |

|---|---|---|---|---|---|

| Benchmark | 5 | 100 | 33.0 | 45.8 | 100 |

| Monocalcium phosphate + Enzymesporin | 5 | 100 | 34.2 | 49.8 | 108.7 |

Furthermore, NIUIF upgraded methods to control feed phosphate production and improve product quality. The project focused on enhancing the consumer properties (reducing the caking and dusting of the finished product) of feed‑grade MCP produced by the Balakovo branch of Apatit.

Pro Agro Lectorium training programme

Since 2021, PhosAgro Group has been running Pro Agro Lectorium, an new training programme for a broad audience, students, and university professors, reaching out to 47 agricultural universities across Russia. Most importantly, the platform is convenient and serves as a source of up‑to‑date information on innovations in the industry from leading scientists and experts for agricultural producers and employees of agricultural companies in Russia and BRICS.

Today, the platform features over 400 lectures, 18 additional professional education courses culminating in the awarding of official state qualifications. Pro Agro Lectorium offers lectures in Russian, English, and Portuguese.

In ProAgro Lectorium, university students can access modern expertise in agriculture and agricultural sciences and better understand the nature of their future profession, graduates can use lectures for a smoother onboarding at a new job, teachers can align their knowledge with the latest scientific developments and self‑study, and seasoned farmers can receive additional training.

Equal opportunities and unhampered access to knowledge make it easier to adapt university curricula to modern labour market requirements, providing students with relevant knowledge and practical skills.

Over 140 speakers from Russia, China, India, Brazil, South Africa, and other countries have already contributed lectures in 22 areas to the platform.

Research as part of PhosAgro’s carbon farm project in the Vologda region

As part of a long‑term climate action, the Company has set up a carbon farm to study CO2 compensation, absorption of carbon emissions by various ecosystems, as well as to test hands‑on solutions for establishing large‑scale carbon farms in agriculture and forestry.

In 2025, PhosAgro Group and the Centre for Forest Ecology and Productivity of the Russian Academy of Sciences will conduct a comprehensive analysis of the two‑year dynamics of carbon accumulation.

| Location | Cherepovets and Vologda districts of the Vologda region at a distance of 100 km from each other |

| Site area | 100 ha of forest plantation and 100 ha of agricultural plantation |

| Study period | 2022–2025 with a possible extension of up to 100 years within the forest plantation |

| Project participants |

|

| Specifications and results of experiments in forest plantations |

|

| Specifications and results of experiments in agricultural landscapes |

|

Key results of the PhosAgro Innovation Centre in 2024:

Trials were carried out to explore carbon dioxide sequestration in forage grasses using the Company’s fertilizers.

Results of testing to study the carbon footprint of fertilizers and their biologised counterparts were obtained at the Russian State Agrarian University – Moscow Timiryazev Agricultural Academy. The nitrogen loss ratio of mineral fertilizers is 0.62–0.94% and 0.59–0.83% for their biologised counterparts with an 8 to 35% reduction in the carbon footprint of the produce.

A pilot was launched to establish an interregional testing network for evaluating the carbon footprint of fertilizers at the Ulyanovsk Research Institute of Agriculture (URIA, a branch of Samara Federal Research Centre of the RAS), the Caspian Federal Agrarian Research Centre of the Russian Academy of Sciences (CFARC of RAS), and the Russian Agrarian State University – Moscow Timiryazev Agricultural Academy.

Preliminary calculation formulas were created for the Agro Calculator for all crops and soil types.

The centre and the Izrael Institute of Global Climate and Ecology (IGCE) are drafting practical recommendations for 100 crops, which will include 50 subsections (methodologies) to be used by farmers. The work helped us acquire experience in using the equipment to estimate carbon gain in ecosystems and the carbon footprint of products.

- together with the Russian Agrarian State University – Moscow Timiryazev Agricultural Academy, develop calculation formulas for assessing the carbon footprint of the plant nutrition system for 38 crops, which will be integrated into the Agro Calculator. Further tests will enable validating the methodology and calculation formulas of Agro Calculator for three climatic zones and three types of soils;

- fine‑tune Agro Calculator simulation models on the basis of a trial on growing ten different crops, which is planned for 2025 at PhosAgro’s farming station in Zemlyaki;

- on the basis of the trial, the IGCE will provide practical recommendations for the voluntary organisation of climate‑friendly agricultural practices for five areas (100 crops).

Cutting‑edge biologised adaptive plant nutrition systems

In 2023–2024, experts from the Company and the Federal Williams Research Centre of Forage Production and Agroecology ran a production trial to cultivate Verko alfalfa using biologised adaptive plant nutrition systems and a biological preservative for forage conservation.

Two biofertilization options were tested during the trial. The first option involved additional use of the Extrasol biological agent and the ApaSil adaptogen (trial plot 1), while the second one relied on replacing ammonium nitrate with biologised urea and using the same nitrogen dose along with ApaSil (trial plot 2).

| Green mass weight in 2023, t/ha | Green mass weight in 2024, t/ha | Total in two years, t/ha | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 1st cut | 2nd cut | 3nd cut | Total in 2023 | 1st cut | 2nd cut | 3nd cut | Total in 2024 | ||

| Check strip | 21.44 | 12.95 | 8.80 | 43.19 | 16.81 | 17.82 | 8.04 | 42.37 | 85.56 |

| Trial plot 1 | 21.66 | 14.18 | 11.60 | 47.44 | 21.12 | 19.70 | 10.20 | 51.02 | 98.46 |

| Trial plot 2 | 23.77 | 15.48 | 12.50 | 51.75 | 27.66 | 23.86 | 11.40 | 62.92 | 114.49 |

In trial plot 1, where the Extrasol biological agent and the ApaSil adaptogen were used, the green mass harvest per area unit for two years was 98.46 t/ha, which is 15% higher than in the ordinary practice.

The maximum yield was achieved in trial plot 2, in the variant where crops were fertilized with biologised urea and treated with the ApaSil adaptogen – 114.49 t/ha of green mass in two years (six cuts), which is 33.8% higher than initially.

Product quality for biologised nutrition systems was also higher, suggesting a high potential for biologised nutrition systems to intensify farming, reduce production costs, improve feed quality for dairy farming, and increase carbon sequestration by forage grass systems.

| 2023, two cuts | 2024, three cuts | |||||

|---|---|---|---|---|---|---|

| Dry matter, t/ha | Crude protein, t/ha | Metabolic energy, GJ/ha | Dry matter, t/ha | Crude protein, t/ha | Metabolic energy, MJ/ha | |

| Check strip | 7.34 | 1.22 | 69.950 | 9.43 | 1.65 | 88.240 |

| Trial plot 1 | 7.61 | 1.24 | 72.585 | 11.91 | 2.06 | 108.050 |

| Trial plot 2 | 8.20 | 1.42 | 78.987 | 13.46 | 2.52 | 124.300 |

Thus, the new types of fertilizers developed by PhosAgro help agricultural producers increase crop yields despite the constraints of limited land resources while also improving forage quality, reducing carbon footprint, enhancing soil fertility, and increasing production margins.

RECSOIL is an international mechanism established by the UN Food and Agriculture Organisation (UN FAO) for scaling up sustainable soil management with a focus on increasing soil organic carbon and improving overall soil health.

In 2024, PhosAgro Group supported by UN FAO and in partnership with the Soil Science Faculty at Lomonosov Moscow State University and AgroGard launched RECSOIL project in Russia.

The project’s key objective is to improve soil carbon content while reducing greenhouse gas emissions through sustainable soil management practices.

- suitable fields (sites) selected for project implementation;

- soil of the selected fields described;

- soil samples taken for lab analysis for a set of physical and chemical indicators.

- adapt low‑carbon agricultural practices in the fields;

- produce crops with low carbon footprint;

- conduct training jointly with UN FAO;

- register RECSOIL as a climate project.

An important project deliverable should be a model of carbon accumulation in soil and calculation of the product’s carbon footprint, which will be integrated into PhosAgro’s Agro Calculator. In addition, the Company plans to develop model methodologies for climate projects similar to RECSOIL, which farmers can use as a template for registering projects as climate projects without the costly step of developing a customised methodology. All this will contribute to building a pool of carbon units formed by nature‑based projects, and, on top of that, establish an effective mechanism for verifying the carbon footprint of premium low‑carbon agricultural products.

Our strategy for innovating and helping students, teachers, and farmers to develop profession competencies relies on partnerships with the leading agricultural universities and R&D centres

Cooperation across a range of areas related to the climate agenda and low‑carbon transition plan

The carbon farm project continued with inventory of seedlings made and data obtained on carbon accumulation by ecosystems with grain‑grass crop rotation and on the cost of carbon units

Work is underway to develop low‑carbon agricultural practices for 100 crops

Work is underway to improve the Agro Calculator

14 research organisations participated in the development of new fertilizers and feed additives, completing a total of 18 research projects

Further progress was made in implementing other projects involving leading Russian scientists to develop and promote new products:

- biotechnologies and feed additives developed;

- registration for new biologised mineral fertilizers launched;

- a pipeline of new promising projects built;

- three patents obtained, 18 videos and 10 publications issued, including three scientific articles

Green Chemistry for Life, a joint grant programme by PhosAgro, UNESCO and the International Union of Pure and Applied Chemistry (IUPAC)

Financial support and scientific guidance for young scientists doing research in emerging Green Chemistry technologies to address environmental challenges and ensure sustainable use of natural resources.

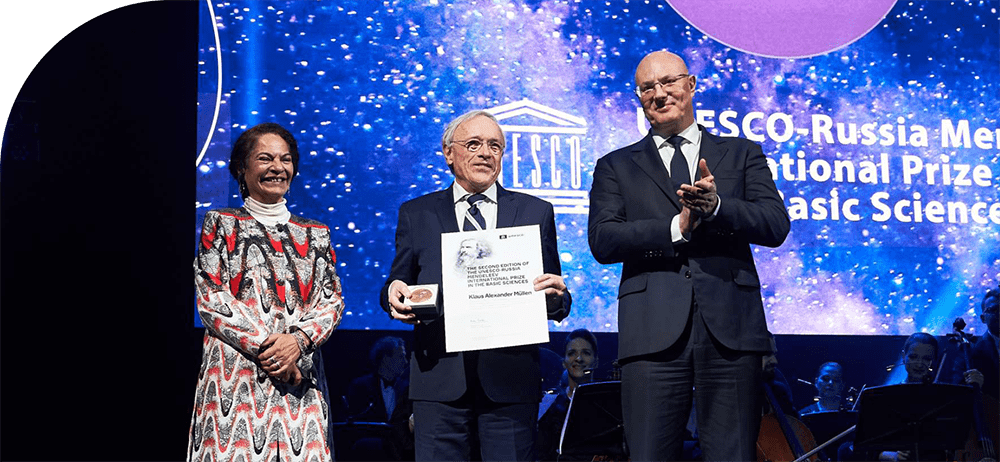

UNESCO‑Russia Mendeleyev International Prize in Basic Sciences

The prize aims to foster scientific progress, basic research popularisation, and international cooperation. The prize is the only award granted for sustainability‑focused research in fundamental sciences under the auspices of UNESCO.

As part of the 10th IUPAC International Conference on Green Chemistry in Beijing, PhosAgro jointly with UNESCO and IUPAC presented young scientists from Russia, Brazil, Portugal, Pakistan, Tunisia, and the UAE with grants for green chemistry research for the eighth time. Over the course of eight rounds of the programme, more than 1,000 applications from young researchers across 120 countries were submitted, with grants awarded to 55 scientists from 33 countries.

In 2024, PhosAgro Group was the general partner at the grant award ceremony of UNESCO‑Russia Mendeleyev International Prize.

Summer Schools on Green Chemistry project run jointly by PhosAgro, IUPAC and Green Sciences for Sustainable Development Foundation

The project is an educational initiative to improve the qualifications of young scientists engaged in green chemistry with a view to promoting innovations.

22nd Mendeleyev Congress on General and Applied Chemistry

The Mendeleyev Congress is held once every five years under the auspices of IUPAC. In 2024, the Congress was dedicated to the 300th anniversary of the Russian Academy of Sciences and the 190th anniversary of Dmitry Mendeleyev.

The sixteenth session of the IUPAC Summer School on Green Chemistry took place at Ca’ Foscari University of Venice, Italy from 1 to 7 July 2024. It brought together 70 young scientists from 33 countries, including 28 African researchers. Since the project’s inception, it has attracted over 1,000 young researchers from 75 countries.

PhosAgro was the general sponsor and partner of the 22nd Mendeleyev Congress on General and Applied Chemistry. Some 4,000 participants from 38 countries attended the Congress, including leading Russian and foreign chemists.

Development of Sustainable Agriculture through the Implementation of the Global Soil Doctors Programme and the Creation of the Global Soil Laboratory Network

The joint project of PhosAgro and FAO promotes the expansion of the Regional Soil Laboratory Network (RESOLAN) in Africa, Asia, Latin America, Russia, and the Middle East, and sustainable soil management among farmers.

Recarbonisation of Global Soils (RECSOIL) project

The UN FAO initiative’s key objective is to improve soil carbon content while reducing greenhouse gas emissions from farm lands through the implementation of sustainable soil management practices.

In 2024, PhosAgro Group and UN FAO signed an agreement to launch stage 3 of the global project for sustainable soil management.

As part of the project, PhosAgro supports UN FAO in implementing the Global Soil Doctors Programme and the Creation of the Global Soil Laboratory Network (GLOSOLAN). Currently, the global network comprises over 1,000 laboratories across 160 countries As part of the Global Soil Doctors Programme, over 11,000 farmers from 20 developing countries. Are improving their knowledge of soil management.

On the occasion of the World Soil Date, PhosAgro, AgroGard, and Lomonosov Moscow State University supported by UN FAO launched a pilot project of the FAO Global Soil Partnership for the Recarbonisation of Global Soils (RECSOIL) in Russia.

PhosAgro contributes by providing expert advice on a wide range of topics on the UN’s global socioeconomic agenda

PhosAgro remains a leader of the UN Global Compact by vigorously supporting the Climate Ambition Accelerator and CEO Water Mandate initiatives to combat climate change and ensure the efficient use of water resources.

During the 29th session of the Conference of the Parties (COP29) to the UN Framework Convention on Climate Change, PhosAgro arranged a session titled “Innovation and artificial intelligence – transformative technologies in climate action” to discuss how to limit the rate of global warming and reduce carbon dioxide emissions.

PhosAgro’s expert contribution to building Africa’s food sovereignty and expanding scientific and educational cooperation between Russian and African universities

Development of scientific and educational potential of African countries, along with the training of qualified personnel for agricultural and chemical industries to build Africa’s food sovereignty.

In 2024, cooperation agreements were signed with leading African agricultural associations – the South African Grain Farmers Association (SAGRA) and the Association for Strengthening Agricultural Research in Eastern and Central Africa (ASARECA).

Pro Agro Lectorium, the Company’s e‑learning platform, was recognised as the official platform of the BRICS Business Council Agribusiness Working Group and won the BRICS Solutions Awards in 2024.

Young Scientists Congress

Partnership in the international promotion of basic research, scientific and educational cooperation and digital education technologies.

PhosAgro Group and the Ministry of Science and Higher Education of the Russian Federation made an agreement at 2024 SPIEF.

PhosAgro Group supported the 7th BRICS Young Innovators contest as part of the 4th Young Scientists Congress. The winners were young scientists from Brazil, China, and Russia. More than 7,000 people from 63 countries took part in the Congress.

Partnership in promoting basic sciences and research in chemistry to further sustainable development as well as the legacy of great Russian scientists Dmitry Mendeleyev

In 2024, PhosAgro Group awarded scholarships to 20 winners of the 5th and 6th competitions of the Laverov scholarship programme established for young scientists from the Mendeleyev University of Chemical Technology in 2022. Since that time, 60 gifted students have been recognised winners of the competition.

In 2024, PhosAgro Group awarded the first ten winners of the Sadykov scholarship programme at the branch of the Mendeleyev University of Chemical Technology in Tashkent.

BRICS International School for Sustainable Agriculture

Partnership in promoting scientific and educational projects in sustainable agriculture, environment, and environmental protection.

In 2024, PhosAgro Group and Peoples’ Friendship University of Russia launched the BRICS International School for Sustainable Agriculture, bringing together 60 students from six BRICS nations: Egypt, India, Iran, China, Russia, and South Africa.

Partnership in scientific research with a focus on sustainable development and green economy

PhosAgro Group, the Diplomatic Academy of the Russian Ministry of Foreign Affairs, and the Russian State Agrarian University – Moscow Timiryazev Agricultural Academy with the support from FAO organised an international symposium for the BRICS countries on climate‑smart and eco‑friendly agriculture. The event attracted more than 300 participants from Russia, Latin America, Asia, and Africa.

Partnership on the European political, scientific and technical agenda for the sustainable use of phosphate resources

In 2024, the Company participated in the 5th European Sustainable Phosphorus Conference that brought together representatives of business, stakeholders, regional and national authorities.

At the event, we presented our best practices of phosphogypsum application.

PhosAgro Group’s expert contribution to the Association’s committees on a wide range of matters as a representative of Russia’s mineral fertilizer industry

In 2024, PhosAgro Group took part in AFA’s 36th Technical Fertilizers Conference and exhibition on the rational use of mineral fertilizers and food security.